Early Color Television

15GP22 Rebuilding

Report

Rebuilding the 15GP22

CRT: A Trip Report from

John Folsom

DAY 1: JUNE 10,

2008 HAWKEYE PICTURE TUBE CO. DES MOINES IOWA

The day

begins early at Hawkeye Picture Tube Co. when owner-operator Scott Avitt

arrives for the days work at 3:30 a.m. A somewhat bleary-eyed and sleep

deprived John Folsom, Bob Galanter, and Pete Deksnis arrived at 3:30

a.m. to find Scott already at work.

The plan was to rebuild the two CRTs I

had sent Scott, a 15GP22 and a 19VP22. The previous afternoon Scott had

prepared the CRTs by giving them a thorough cleaning to remove the

external aquadag coating, dirt, and debris, which might tend to foul the

oven.

The first task was

to let air into the CRTs, both of which were still under vacuum. Scott

used a compressed air drill with a smooth pointed carbide bit. The bit

is held against the neck of the CRT near the base, and the high-speed

rotation and pressure causes enough friction to melt a very small hole in

the glass. Once the pointed tip of the bit penetrates the glass, it is

withdrawn and air begins to enter the tube. It takes 10 to 15 minutes

for the tubes to equalize with the outside air pressure. Once at ambient

pressure, Scott scores a line on the neck of the tube with a diamond file

and places a nichrome hot wire around the neck of the tube. When the

wire is heated ,it causes the scratch made by the file to propagate

around the neck of the tube, resulting in a clean cleavage of the glass.

Scott extracts the old gun and then washes out the neck of the tube to

remove the old getter material.

SCORE THE NECK

HOT WIRE

THE OLD GUN

NECK WASHING

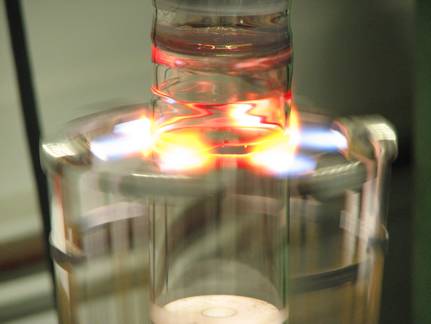

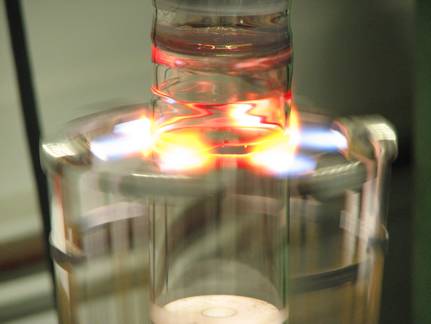

Next, the CRTs were

placed ina warming oven at approximately 180-degrees F to prevent

condensation while Scott prepares to weld a new length of neck glass onto

each tube. This welding is performed in a vertical lathe, where the CRT

is held stationary and the gas flames rotate around the neck of the tube.

THE VERTICAL LATHE

The CRT is

suspended from above, and the new piece of neck glass rests on a Teflon

necking pin, which sits atop a chuck. The steering wheels in front of

Scott allow him to move the chuck or rotating flames up and down.

ALIGNING NECK GLASS IN

LATHE

POSITION GLASS FOR

WELDING

FLAME ON!

As the flames

rotate, Scott raises and lowers them to slowly heat the glass above and

below the area to be welded in order to prevent thermal shock and

breakage. As the glass warms, Scott slowly raises the temperature of the

flames, and decreases the up/down travel.

GETTING HOT

When the edges of

the two glass pieces reach the right temperature, Scott raises the chuck

until the edges touch, and the weld is made.

MAKING THE JOINT

The joint is slowly

cooled under the flames, annealing the glass to relieve stresses built up

by the temperature gradient.

COOLING OFF

THE WELD IS

COMPLETE

Next, the new gun

is positioned in the neck of the tube. Scott made measurements and marks

on the CRT prior to removing the old gun to let him know where to

position the new gun in the neck. The gun is held rather tightly in

place by little springy fingers mounted around the gun. Scott folds the

wires on the button tight against the stem so they will fit inside the

chuck on the vertical lathe.

NEW GUN

The CRT is placed

atop a hotbox at about 550-degrees F with the neck and gun inside the

box. This thermally prepares the neck and gun assembly for sealing the

button into the neck. The button is the round piece of glass through

which the wires extend. The stem is the hollow piece of glass at the

center of the button through which the CRT is evacuated.

THE HOT BOX

Now back into the

vertical lathe to weld the new gun in place. The end of the chuck is a

hollow conical shaped metal piece, which Scott raises to be flush with

the bottom of the button. The evacuation stem with the wires pressed

against it fits down inside the center of the chuck. The cone supports

the button and shields the wires and evacuation stem from the heat of the

flames. In a manner similar to the procedure for the neck extension

weld, the glass is slowly heated until it reaches the proper temperature.

READY TO SEAL

HEATING

As the neck glass

continues to heat, it eventually reaches a temperature where it softens

to the point that it begins to stretch out under the influence of

gravity. The glass below the heated area falls until it is stopped by the

spring wrapped around the chuck. As it falls, the neck glass

stretches out, thins, and pulls inward until it makes contact with the

edge of the button. The amount of "fall" is critical and is controlled by

the placement of the spring on the chuck. Scott continues to pour on the

heat, and the neck glass fuses to the rim of the button. The thin curtain

of glass below the button is broken as Scott blows puffs of air

up through holes in the chuck. This, along with the action of the flames,

cuts off the curtain of glass.

THE FALL

Once again, the

glass is cooled slowly under the flames.

COOLING

THE BUTTON IS

SEALED INTO THE NECK

Next, Bob Galanter

applies a bead of VACSEAL to the glass-to-metal seals on both sides of

the metal flange at the face of the CRT.

VACSEALING

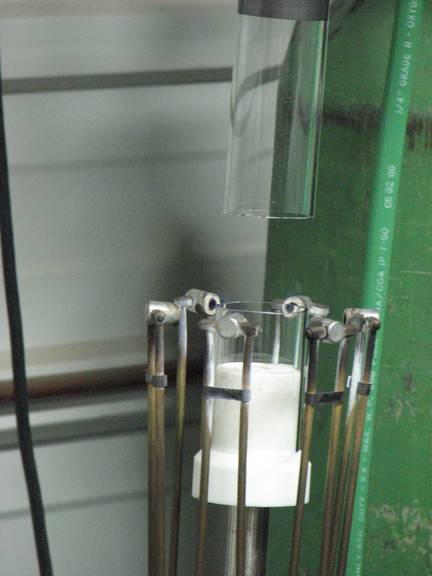

The CRT is placed

on a rack in the exhaust cycle oven.

THE OVEN SETUP

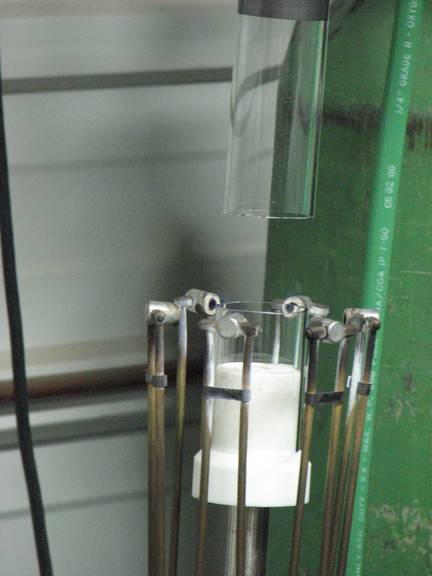

The CRT is

suspended in a holder in the oven above the exhaust port. The port is

connected to the vacuum pumps below the floor of the oven. A mechanical

pump draws outmost of the air from the CRT, while a diffusion pump

achieves the very high vacuum required for CRTs to operate. The stem of

the CRT fits down into the open hole of the exhaust port. A rubber

bushing slides tightly onto the stem, with a knurled threaded cap above

it. When screwed down onto the port, the cap compresses the rubber

bushing makes a vacuum-tight seal with the glass stem. The whole port

assembly is cooled by a water jacket. Above the port on the stem is a

pinch-off coil. This is an electric heating element that is energized at

the end of the exhaust cycle. Heat from the element softens the glass

stem until air pressure causes the stem to collapse, pinching off the

vacuum in the CRT. Note that the button wires are now flared out to allow

the pinch-off action to be close to the button. Around the neck of he

CRT is the so-called bomber, a RF induction coil used to heat the

elements of the gun during the evacuation cycle to drive out more of the

stray gas molecules.

OVEN SETUP

The gas-fired oven

is controlled by a simple cam and leaver system driving a sequence of

relays to activate the various steps in the exhaust cycle.

THE CAM

OVEN CONTROL AND

STATUS INDICATORS

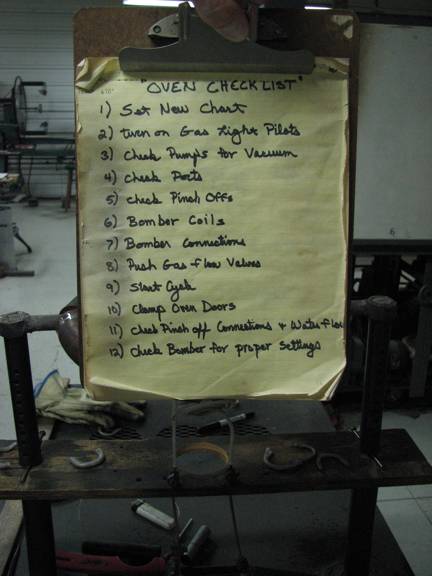

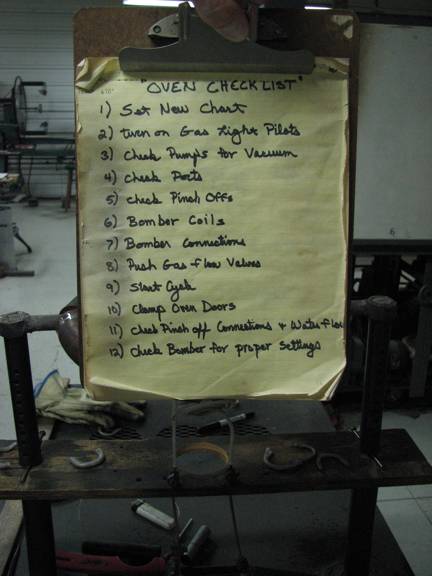

Scott has a

checklist he follows religiously for each position in the oven prior to

initiating the exhaust cycle. One the cycle starts it must run to the

end. Scott can override some actions in the cycle for each station in

the oven, such as the vacuum pumps, bomber coil, or pinch-off coil

operation, should there be a problem with a particular CRT while in the

oven.

THE CHECKLIST

The arm rides along

the spiral edge of the cam and controls the oven temperature. The cam

rotates once in about three hours and slowly increases the oven

temperature to approximately 650-degrees F. Scott then flips the cam

over, and the oven begins to cool during the following three-hour period.

The exhaust cycle

starts with activating the vacuum pumps and bringing the oven up to

temperature. Then the bomber coil is activated, further heating the gun

elements and improving the quality of the vacuum. As the oven cools,

the pinch-off coil is activated, sealing off the vacuum in the CRT. The

oven is left to cool completely overnight.

DAY 2: June 11, 2008

Scott

took pity on us and told us we could sleep in until 4:00 a.m. the morning

of the second day. We arrived full of anticipation. "Bad news" announced

Scott as we entered the door. About an hour into the oven cycle,

when the temperature had reached about 600 degrees F, Scott heard a

whistle from the15GP22 station in the oven. He turned off the vacuum

pumps, bomber coil, and pinch-off coil for that oven station and allowed

the oven to complete the exhaust cycle. The 19VP22 and 12UP4 CRTs ,

which occupied two other stations in the oven, completed the exhaust

cycle nominally.

We opened the now

cool oven and examined the 15GP22. The failure occurred right where the

stem joined the button. This was possibly caused by a shift inthe CRT

position on its holder in the oven, or from a build up of lateral forces

on the stem during the heating.

THE DAMAGE

For the 19VP22 CRT,

the next step was to flash the getters. The horseshoe shaped ring is an

RF induction coil used to heat the getters, causing the oxygen scavenging

material in the getter to boil off and deposit on the inside surface of

the neck of the CRT. This helps to further improve the quality of the

vacuum in the CRT.

FLASHING THE

GETTERS

Next, high-voltage,

pulsed-AC is applied to all the pins of the CRT while the anode is tied

to the AC return. This is done to burn out any residual debris within the

gun structure. Then the cathodes are activated by heating them using

elevated voltage applied to the filaments. Last, a new base is soldered

to the wires of the button and affixed with silicone RTV.

THE WAY FORWARD

The failure of the

15GP22 is both good and bad news. It is, of course, bad news that it did

not make it through on the first attempt. But the stem failure is

mostly good news, as this type of failure is uncorrelated to the fact

that it is a 15GP22. This failure can likely be corrected by ordering

stems with a stouter tubulation. Back in 2003 when Bruce Buchanan and I

were first discussing this with Scott, he indicated to Bruce that a 0.25"

O.D. tubulation was what he wanted on the stems. But this now seems to

have been a miscommunication of some sort between Scott and Bruce. So

new stems will have to be ordered. The good news, they are still

available.

This photo

illustrated the differences in the tubulation on our stem (right)

compared to the now preferred tubulation (left).

TUBULATION

The VACSEAL cured

very nicely, and though this tube did not have a leak, this seems to

offer some hope that VACSEAL may be useful in stopping leaks. But this

will have to be proven when the day comes to attempt a rebuild of a

leaker CRT.

In order to rebuild

a 15GP22,you need a replacement gun. However, no new or new-old-stock

guns for the 15GP22 are available. South West Vacuum rebuilt two 15GP22

guns for me by replacing the heaters and cathodes and attaching the

rebuilt gun to the new button. But this service is not longer available

from South West Vacuum. While attempting to seal in the first of these

guns into the15GP22, Scott failed to achieve a proper seal between the

button and the neck, so he cut the first gun out and used the second

gun. This leaves us with no rebuilt guns.

After removing the

failed CRT from the oven, the gun was removed and the CRT sealed with a

resin tape to prevent moisture from getting in. It now awaits the next

rebuilding attempt.

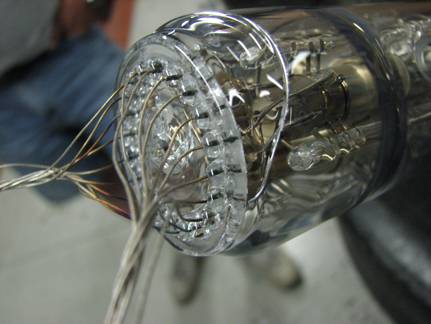

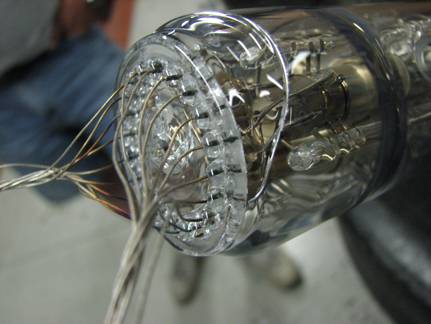

The two 15GP22 guns

removed are undamaged, and the cathodes are still good. However, they

are both now attached to damaged buttons which cannot be reused. In

order to put a new button on, it is necessary to remove the heaters and

cathodes and replace them with new ones, because the structure of the

heater and cathode attachments to the button wires are too frail to

survive any attempt at a button transplant.

Bob Galanter has

taken on the task of attempting to rebuild guns for the 15GP22. Our

research so far leads us to believe it is doable. In parallel, we are

pursuing a solution from the French CRT company RACS.

But the clock is

running….Scott will retire in about two years, so we would like to

squeeze in as many rebuilds as possible.

Stay tuned for

future developments!

Rebuilding the 15GP22: A Final Report

Late in February 2010, Bob Galanter and I traveled to Hawkeye Picture Tube Co. in Des Moines, IA to have another go at rebuilding 15GP22s. Bob and I each brought an under vacuum dud tube, and a known leaker tube. The plan was to rebuild the two tubes that were under vacuum, and have Scotty install dummy guns and stems on the two leakers, so we could take them to a Michigan University lab for leak testing.

We had with us some of the redesigned Richland stems used successfully to rebuild the first 15GP22, and several rebuilt 15GP22 gun assemblies mounted on the new style Richland stems.

Scotty first installed the dummy guns and stems onto the two

leaker tubes without incident. Next he installed rebuilt 15GP22 guns onto the two under vacuum 15GP22s. One of the two stems that were mounted to the

under vacuum tubes, cracked while the tube was cooling down. We had extra guns, and the second attempt was successful.

The two "non-leaker" tubes went into the oven and began the baking and evacuation cycle. Bob's tube had aluminum filled high temperature epoxy applied to the glass to metal joints around the flange of the tube. My tube had vacseal applied to the same areas.

Within a couple of hours, the mechanical backer vacuum pump was making gurgling noises. (this sound from the pump is a sign that a tube is leaking) The pump for Bob's tube was turned off. Bob and I went to the motel room for the evening.

In the morning, Scotty informed us that my tube had also failed in

the oven, during the tip-off cycle. Tip off is is where a electric heating element heats the glass exhaust stem and causes it to melt and collapse, sealing the tube shut. Opening the now cool oven door revealed the following damages.

Bob's tube had failed because the epoxy material's difference in temperature coefficient of expansion, had pulled up flakes of glass from the surface, which propogated a crack around the face of the CRT, at the glass to metal joint. A whack with a rubber mallet separated the faceplate from the front of the CRT.

My CRT had failed due to a crack in the stem. And in addition, there was a crack in the phosphor dot plate. So this leaves both of these tubes destroyed.

Later that week Bob and I took the 2 leaker CRTs and a curing oven to a Michigan University lab where leak testing was performed using a helium leak detector. This equipment consists of a mechanical vacuum pump and a turbo-vacuum pump, which can evacuate the CRT rapidly, and a mass spectrometer that looks for the presence of helium in the exhaust from the CRT.

Leak checks on Bob's tube revealed two closely spaced leaks at the edge weld where the 2 metal flange pieces were heli-arc welded together. Leak checks on my tube revealed leaks at the glass to metal seams.

Bob attempted to seal the leak in his tube by apply a non-filled version of the high temperature epoxy, but it was not

possible to keep the epoxy in place on the leaks where we wanted it, and so the attempt to seal these weld leaks failed.

We put vacseal on the glass to metal joints on my tube, and within the limits of the equipment, it appeares that the leaks have been sealed.

We had also brought with us, a 21AXP22 CRT which Scotty had previously rebuilt for me, which had leaked after removal from Scotty's oven. Leak checks on this tube revealed a leak at the flange weld line on this tube. These leaks in the welds on the CRTs was unexpected, and adds a new level of complexity to our problems.

Bob and I returned to our respective homes, and the three leaker CRTs stayed with Bob. He began some experiments on a flange from a broken 15GP22 to see if he could braze the flange weld. Preliminary results are encouraging.

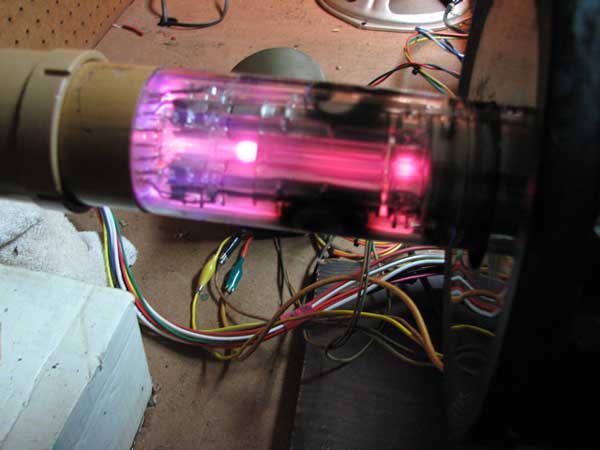

Today I was troubleshooting a strange and difficult to isolate high voltage arcing problem with my Motorola 15" color set. I decided to use the only successfully rebuilt 15GP22 from our attempt back in November of 2009, to determine if the problem was with the Motorola CRT or mounting fixture. Both the Motorola CRT and the rebuilt 15GP22, are mounted on slide-in wooden CRT holders, so it was easy to simply swap CRTs on their holders, and put the Motorola yoke on the rebuilt CRT.

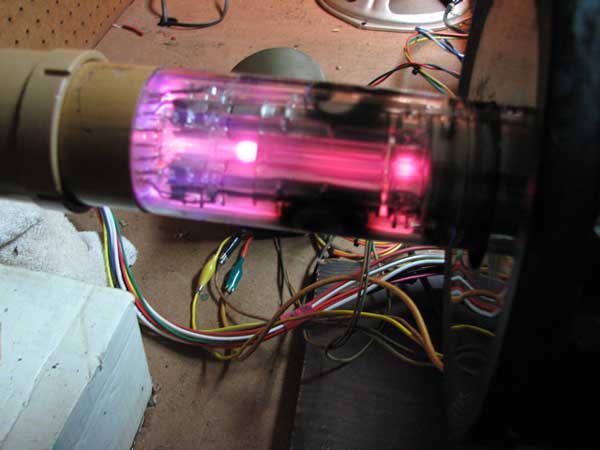

Upon power up, there was no raster. A few quick checks revealed a dreadful purple glow in the neck of the rebuilt 15GP22! Argggggh! The tube has sprung a leak.

Discussing this with Bob, and considering everything we have done to date, and the fact that we still have unresolved stem cracking issues, we agree that we can no longer justify the expense of additional attempts to rebuild tubes. Maybe in the future, if CRT rebuilding can be set up at the ETF museum, and the overhead cost of rebuild attempts becomes much lower, we may consider continuing the effort. But for now at least, I think we have done all that we can justify doing.